3D Printing vs. Additive Manufacturing: Easily Explained

Unpacking the Differences and Similarities

In today’s world of creative manufacturing, people often say that “3D Printing” and “Additive Manufacturing” are synonymous terms. Despite the close ties, there are definitely differences to be recognized. Essentially, you can use the term Additive Manufacturing (AM) in place of 3D Printing (3DP), but not the other way around.

Additive Manufacturing is the broader term that refers to any process that creates objects by adding material together. This can involve a variety of techniques, including but not limited to 3D Printing. On the other hand, 3DP, specifically refers to creating objects by laying down successive layers of material. It’s a more specific type of Additive Manufacturing that has become widely popular due to its accessibility and ease of use.

Additive Manufacturing is The Broader Canvas

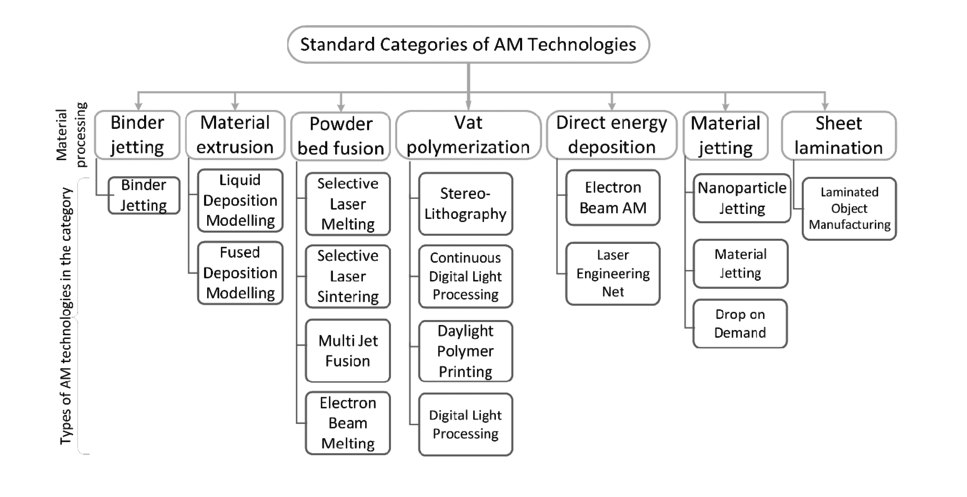

As you see in the chart, Additive Manufacturing (AM) includes many different processes and technologies for making 3D objects. This term means the method of creating items by adding material layer by layer in different ways such as extrusion, laser, jetting, etc…, instead of cutting away from a solid piece like in subtractive manufacturing. This fact make possible to create complicated shapes, hollow objects, and detailed designs that maybe cannot be done with more traditional techniques.

Some important known processes of AM are:

• Stereolithography (SLA): Uses lasers to solidify liquid resin layer by layer.

• Selective Laser Sintering (SLS): Utilises a laser to fusing powdered materials like plastic or metal together.

• Fused Deposition Modeling (FDM): This is the 3D printing method most people use. It works by pushing melted plastic filament out to create an object layer by layer. (a technique under extrusion process in the chart)

• Electron Beam Melting (EBM): This method uses electron beam to melt metal powder, which makes it perfect for creating high-performance parts.

3D Printing is A Specific Type of AM

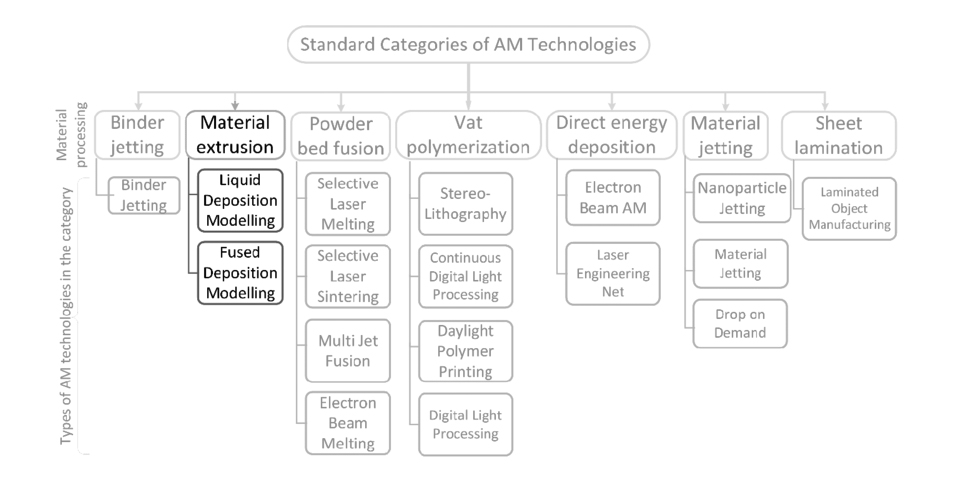

3D Printing is a one of the subcategory of Additive Manufacturing so also makes use of a computer-aided design (CAD) file to build something physical. It works by putting material down layer upon layer, often using things like filaments, powders, or resins. (As you can see in the darker color in the second chart, we highlighted 3DP process which is Material Extrusion and a couple of technologies with that process)

Here are some key characteristics of 3D Printing:

• Very accessible: Compared to other AM technologies, 3D printers are usually cheaper and simpler to operate. This makes them favorite choices for hobbyists, artists, and small businesses.

• Material limitations: While materials are expanding, 3D Printing often uses plastics or polymers, In contrast AM can work with metals, ceramics, and even biomaterials.

• Layer visibility: Due to the layer-by-layer approach, 3D printed objects may show visible lines or have a slightly textured surface.

Choosing the Right Technology

When choosing between 3D Printing and the Additive Manufacturing processes, consider the following factors:

• Complexity of the design: For complex details, both techniques can perform effectively. However, some Additive Manufacturing processes provide smoother surfaces.

• Material needs: If you need a specific material like metal or high-performance plastic, AM here offers a wider range of options.

• Budget and scale: 3D Printing can be more economical for smaller projects, while AM gives industrial-level choices suitable for bigger production quantities with more precision.

The Future of Additive Manufacturing

Additive Manufacturing techniques are changing quickly with lots of potential. As materials get better and processes improve, we can look forward to making even more complicated and high-quality objects using these techniques. The future of manufacturing probably will see traditional and new additive methods working together more closely, giving even bigger design freedom and making production more flexible.

The Bottom Line

Think of 3D Printing as a member of Additive Manufacturing family. 3D printing focuses on a specific technology (layered deposition by extrusion) and uses readily available materials, making it accessible for hobbyists, artists and smaller projects. Additive manufacturing, on the other hand, includes a wider range of advanced techniques and materials, that serve industrial uses needing high accuracy and various types of materials. So, the next time you hear these terms, you’ll be equipped to understand the difference between them.

Further studies

If you are interested in knowing more in detail about Additive Manufacturing techniques, we suggest you the “Additive Manufacturing Technologies” book, also available on Amazon, and you can also download a great detailed map from this website.